Add to Cart

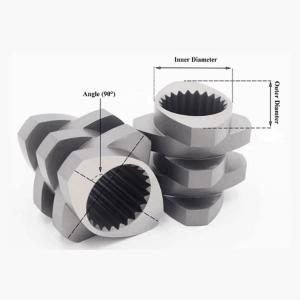

Customized Screw Element for Twin screw extruder

1. Descriptions

Screw element type for each function: Feeding, Melting, Mixing, Venting, Pressurization

The intermeshing screws co-rotate and wipe each other with narrow clearance so that no residues are left in the screw flights and cleaning effort is thus reduced.

The function of screw element si mainly used to convey materials. Feeding and degassing sections generally have the long pitch to improve the material conveying and degassing. For material of low bulk density, feeding sections can use deep channel components to increase feeding capacity. The metering extruded segmented screw elements generally adopt the small pitch which is used to pressurize, improve the density of the material at the die head, and make the extrusion more stable.

The kneading block is generally used for melting and mixing of the material. Heat energy is generated by mechanical shear. Together with heating of the barrel, material can be melted and mixed quickly, with special elements to distribute the material more evenly.

| Code | Product code | Materisl alloy | HRC | Corrosion resistance |

| A | BLM-02 | nickel base alloy | 52-56 | 8 |

| B | BLM-03 | nickel base alloy | 52-56 | 9 |

| C | BLM-04 | nickel base alloy | 40-45 | 8 |

| D | BLM-05 | Nickel base tungsten carbide alloy | 56-60 | 8 |

2 .Twin screw extruder screw element parameter:

| Model | Screw Major Diameter (D/mm) | Screw Minor Diameter (d/mm) | D/d | Center distance(mm) |

| BM-20 | 21.7 | 14 | 1.55 | 18 |

| BM-25 | 25 | 16.1 | 1.55 | 21.2 |

| BM-35 | 35.6 | 23.6 | 1.51 | 30 |

| BM-50 | 50.5 | 32.5 | 1.55 | 42 |

| BM-52 | 51.4 | 33.8 | 1.52 | 43 |

| BM-60 | 59.6 | 43.8 | 1.37 | 52 |

| BM-65 | 62.4 | 40.5 | 1.54 | 52 |

| BM-68 | 69 | 49 | 1.40 | 60 |

| BM-70 | 70.6 | 47.4 | 1.49 | 60 |

| BM-75 | 71 | 47 | 1.51 | 60 |

3. The screw shaft system is characterized by the following:

Screw elements with various pitches and lengths

Kneading blocks with various angles of stagger, numbers of kneading disks and disk widths

Screw tips to fix the screw set axially

Gear teeth connection to ensure power flow between the screw shaft and screw elements.

4 . Pictures: